Dark store kitchen

The kitchen is one of Samokat's new projects and is responsible for fast delivery of hot meals to clients

The business prioritizes fast order assembly and quick handoff to delivery.

Metrics

• Time to Task

• Speed of taking a task into work

• Product quality

• Speed of taking a task into work

• Product quality

DAU

400 operators

Dark Stores

240

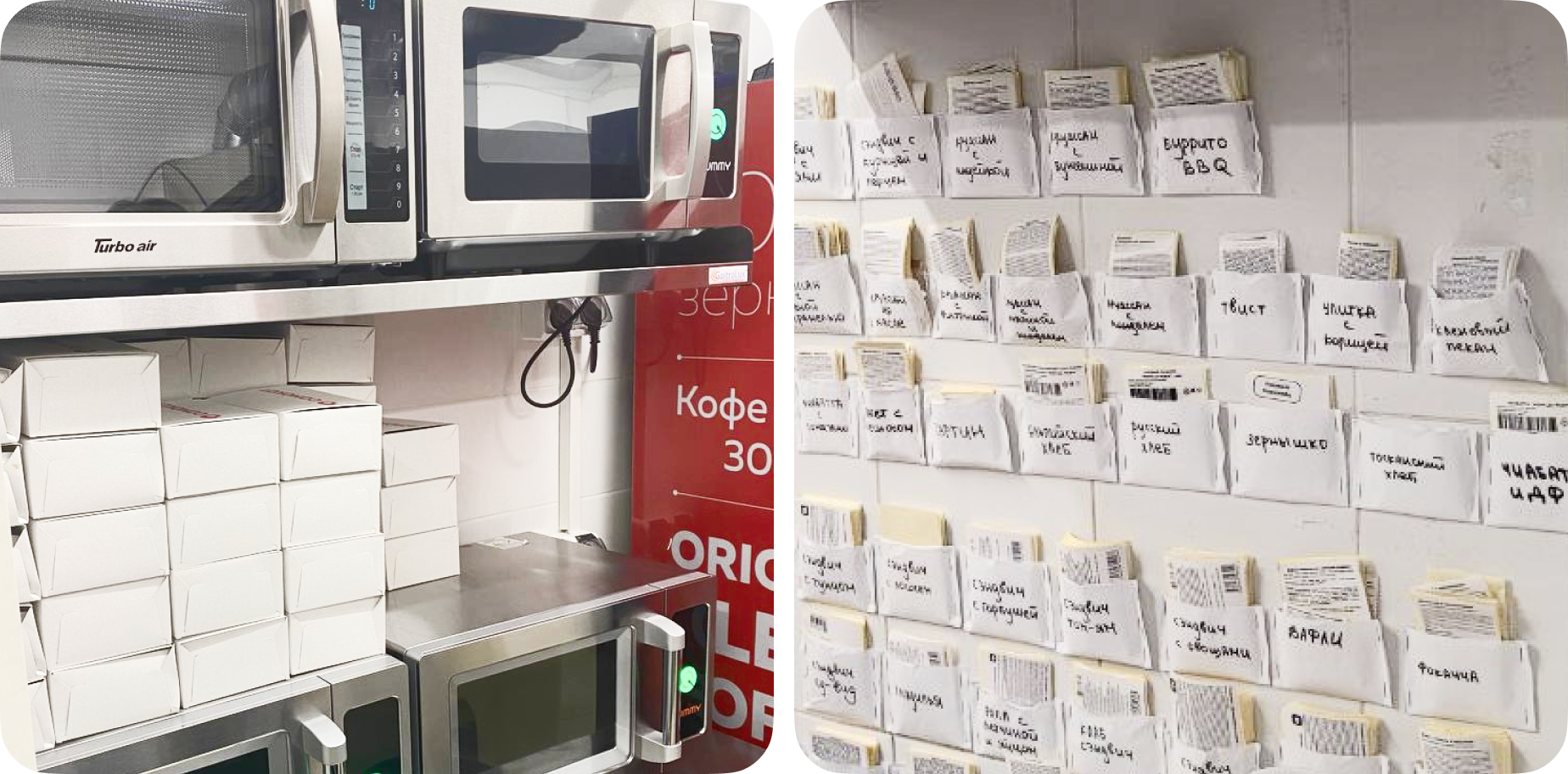

In the physical workflow, the operator finds the items from the order and puts them on heating. After that, they need to prepare labels with ingredients and production dates for the meals. Without a label, the meal cannot be handed over for delivery.

Problem

We identified a significant number of food order cancellations from kitchens

Labels are printed and distributed by a supervisor to dark stores with kitchens. Operators use pre-printed labels to hand meals over for delivery. If the recipe changes or a label is missing, the meal cannot be delivered to the client.

My role

Worked end-to-end on the project: from discovery and problem definition through design to final release

• Joined at the stage of active kitchen rollout.

• Conducted field research in 2 dark stores.

• Identified key issues affecting Time to Task, errors, and item removal from orders.

• Together with the product manager, we pitched the idea of label printing to the business (at that time, labels were printed and distributed by a supervisor).

• Conducted 10 UX tests

• Together with the product manager, ran a technical launch in 10 dark stores.

• Released the updates to 240 dark stores

Busines pain points

Labels are expensive; if the recipe changes, the entire batch is written off

An item is removed from the order if labels run out or expire

Labels are printed in advance and distributed across warehouses

Many people are involved in distributing labels across warehouses

Kitchen operators' pain points

Forced to search for the correct label

Labels run out or become outdated

If there is no label, the item is written off

There is a need to spend less time

The main insight

The app should help operators have only order-relevant, up-to-date labels at hand

Hypotheses

Printing labels during order assembly will reduce the supervisor's workload

Involvement of additional staff

Label printing will increase product availability on the storefront

Availability, profit

Label printing will speed up assembly and reduce cancellations

Time to Task

Label printing will eliminate the need for pre-printing resources

Additional resources

Label printing will eliminate the issue of disposing unused label batches

Additional resources

Label printing will eliminate the problem of removing items from orders

Write-offs, customer experience

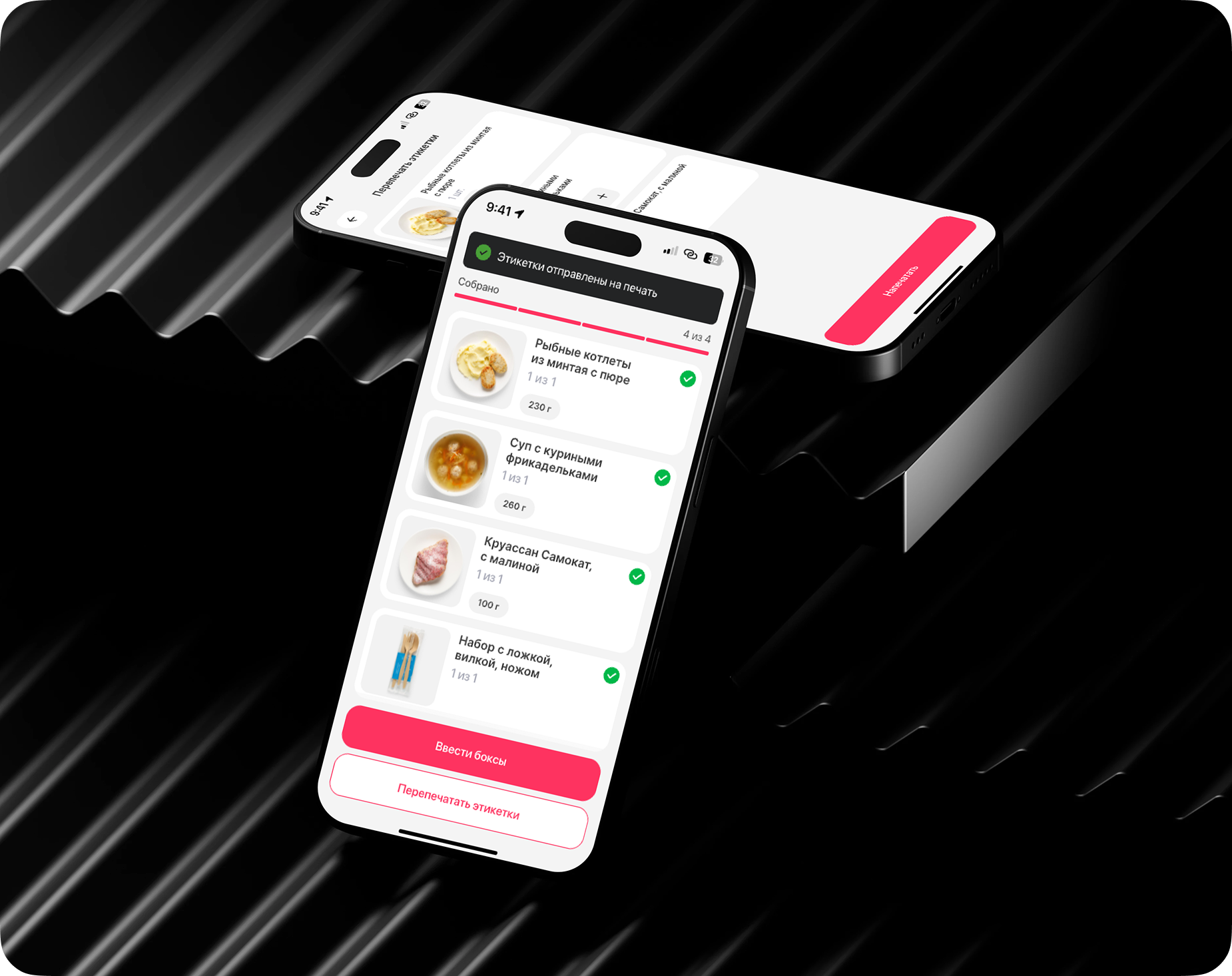

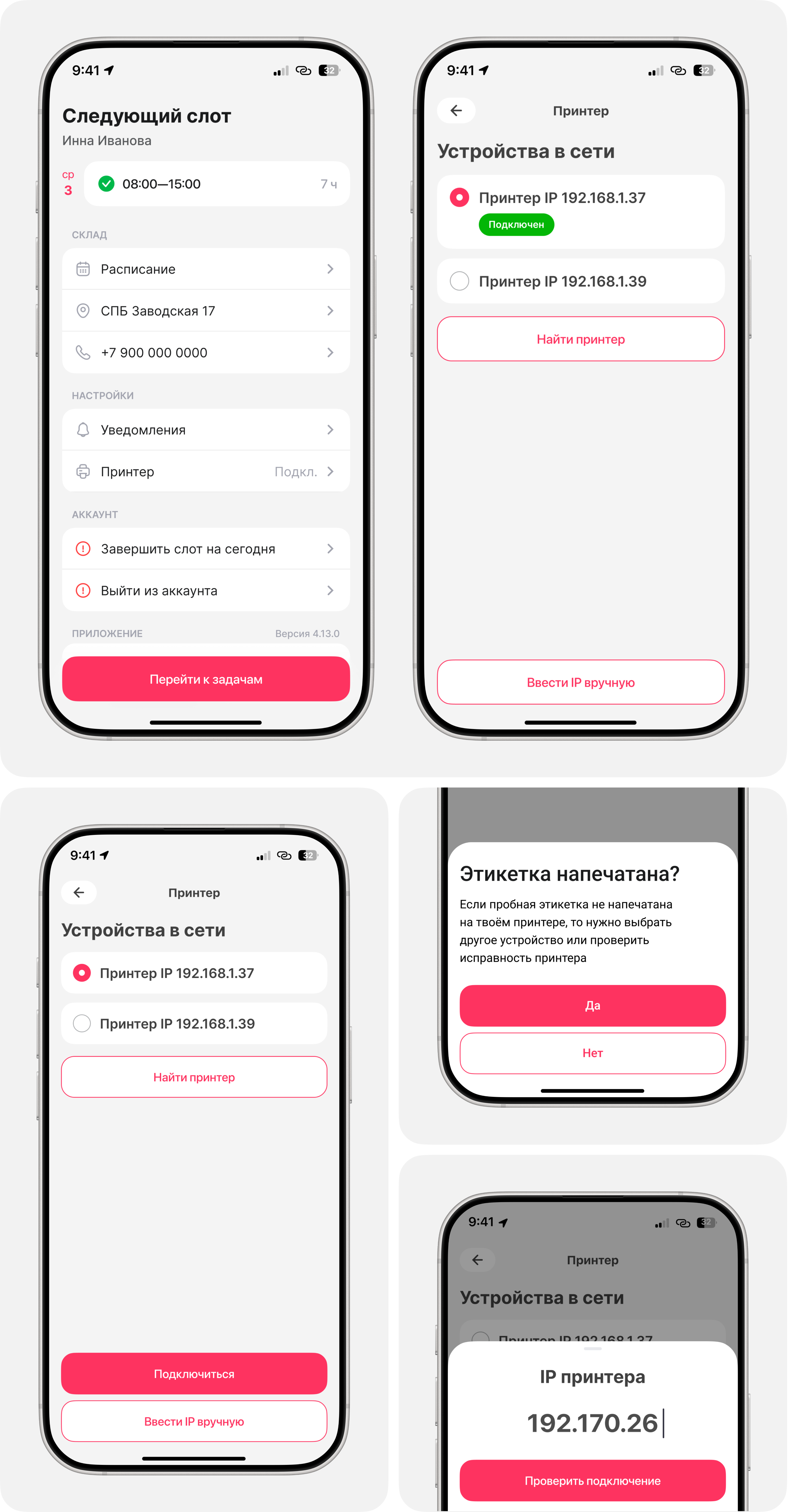

Printer integration

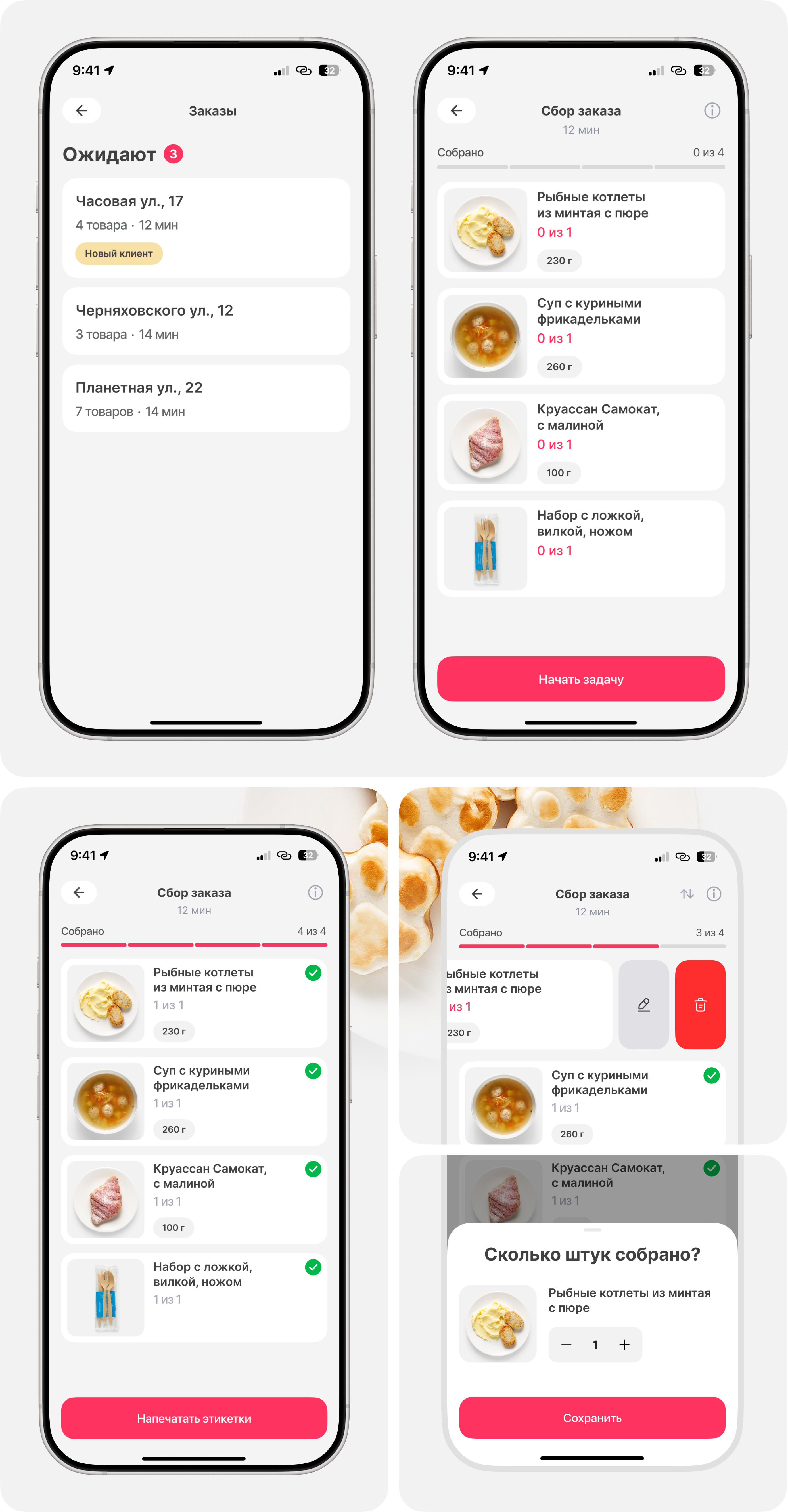

Start of assembly

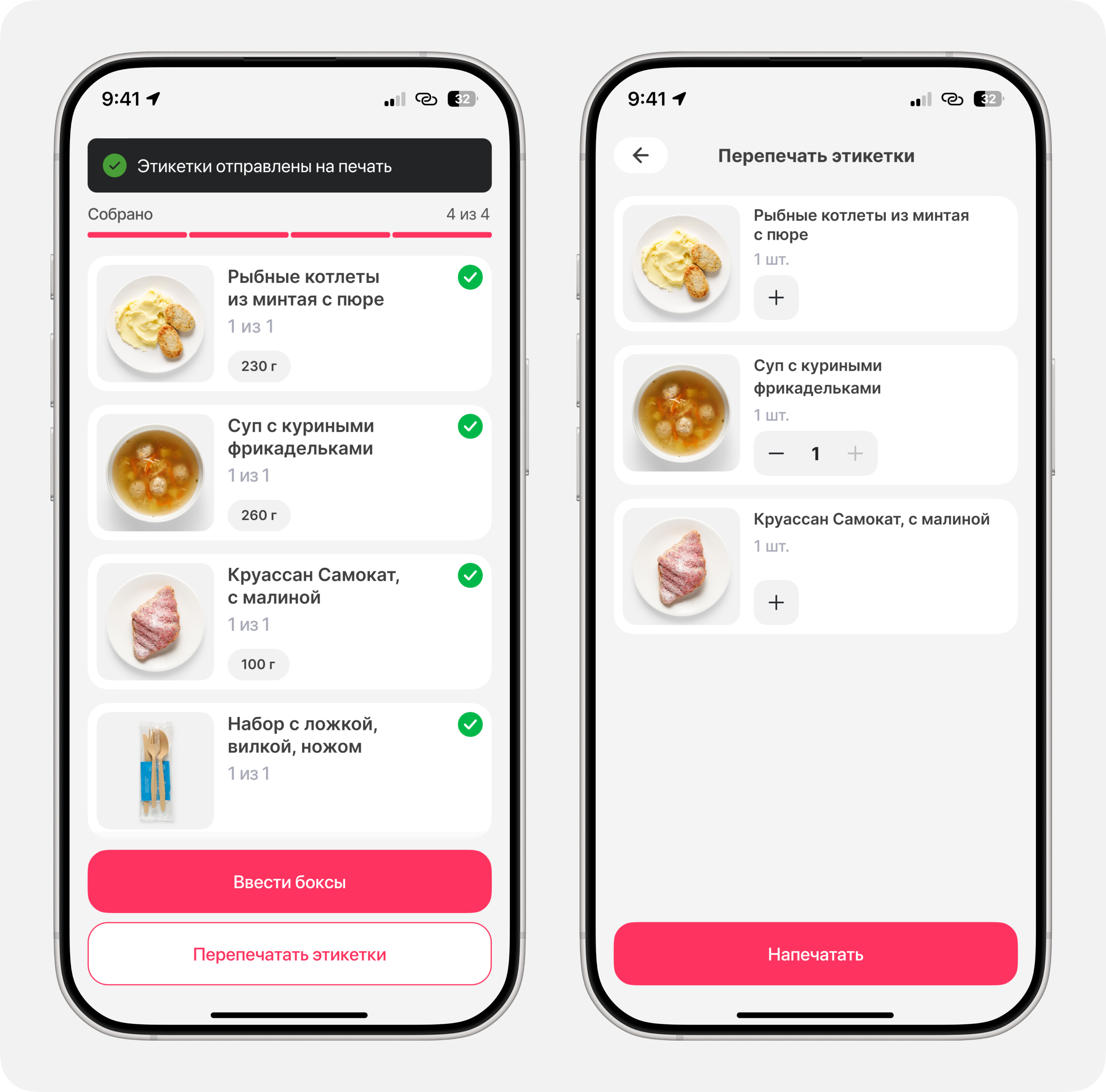

Kitchen operators mark the goods as collected, reheat them, and proceed to print labels

Label printing

If the label has not been printed or has been damaged, it can be reprinted

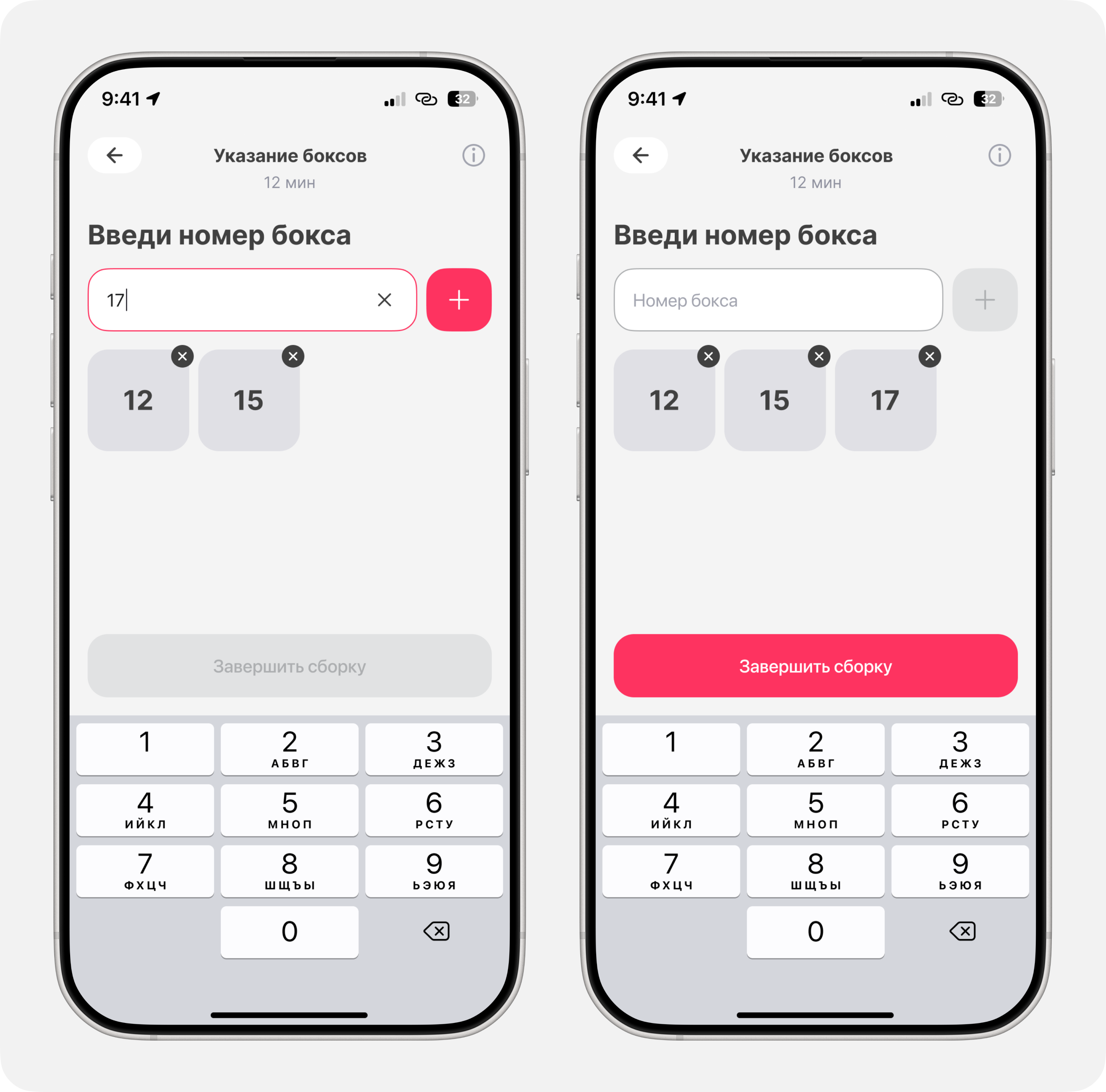

Entering box numbers and completion

To complete the task, you must enter the box numbers to transfer the order for delivery

Result

Together with the product manager, ran a technical launch in 10 dark stores.

Released the updates to 240 dark stores.

-12M RUB

Savings from label printing and canceled orders per year

-10%

Supervisor workload

-5%

Canceled orders

Label printing allowed kitchen operators to spend less time searching and hand off orders faster